TM 5-5420-208-12&P

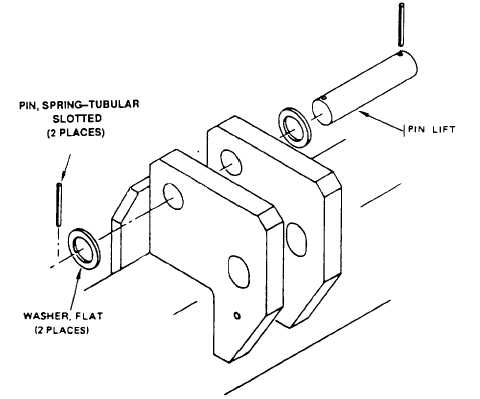

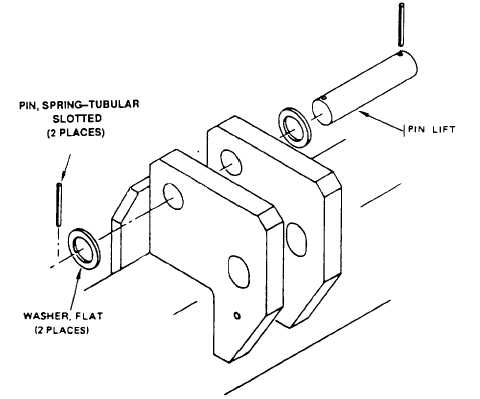

Figure 4-3. Lift Pin, Removal and Installation.

b. Inspection and Repair

(1) Inspect lift pin for cracks and gouges.

(2) Repair of lift pin is limited to replacement.

c. Installation.

(1) Install one spring pin through hole in lift pin using brass punch or soft hammer.

(2) Place one washer on lift pin.

(3) Slide lift pin through lift plate holes.

(4) Install remaining flat washer.

(5) Install remaining spring pin.

4-13. Axle, Roller and Bearings.

a. Removal.

(1) Using proper sized drift pin, drive spring pin into axle as far as it will go (figure 4-4).

(2) Use a soft driving pin and drive the axle out of the support plates and roller.

(3) Remove roller.

(4) Use drift pin to drive spring pin

b. Cleaning and Inspection

WARNING

Dry-cleaning solvent, Specification P-D-680, used to clean parts is potentially

dangerous to personnel and property. Avoid repeated and prolonged skin contact.

Do not use near open flame or excessive heat. Flash point of solvent is 100

degrees F to 138 degrees F (38 degrees C to 59 degrees C).

(1) Clean roller and axle with cleaning solvent, item 1, Appendix E. Dry with low pressure compressed

air.

(2) Inspect the roller assembly for damage and worn bearings.

(3) Replace any worn or damaged parts.

(4) Pack roller bearings with grease, item 2, Appendix E.

(5) Apply grease, item 2, Appendix E, to axle.

4-5